Beautiful Plants For Your Interior

Under the Microscope: The Impact of Fiber Damage on Needle Felted Pets Sculpture Longevity

Published by The Professional wool felt team

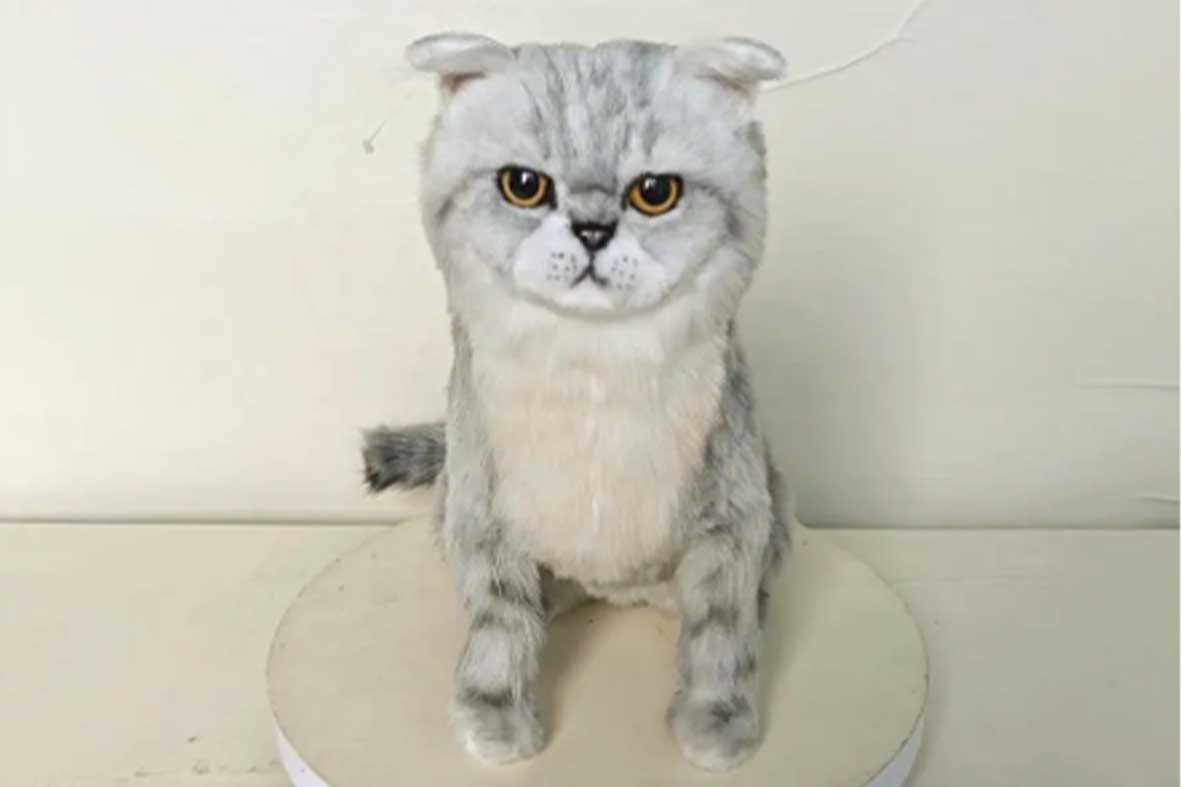

Imagine this scenario: You commission a custom replica of your beloved Golden Retriever who passed away last year. When the box arrives, it’s emotional. The likeness is there. The fur looks soft. It sits on your mantlepiece, a perfect tribute.

But three months later, something subtle happens. The perky ears start to droop. The defined shape of the snout softens into a vague, fuzzy lump. Six months in, when you pick it up to dust the shelf, it feels “squishy,” like a marshmallow losing its air. The fur begins to shed, leaving a halo of loose fibers around the base.

Why does this happen?

The answer doesn’t lie in the artistic talent of the creator. It lies under the microscope.

At our studio, we believe that a memorial piece should last as long as your memories—forever. To achieve this, we don’t just “poke wool.” We apply principles of material science, physics, and biology. Today, we are taking you into the laboratory to explain the relationship between fiber damage, needle depth, and structural longevity.

The Executive Summary: A needle felted sculpture is a battle against entropy. Cheap, quickly-made pieces rely on “surface tension” that fails over time. Heirloom pieces rely on “deep-core entanglement” and the specific biological locking mechanisms of wool scales to create a structure that rivals solid wood in density.

The Microscopic Architecture: Nature’s “Velcro”

To understand why our prices reflect hundreds of hours of labor, you first need to understand the material: Wool. It is not just a strand of hair; it is a complex biological structure.

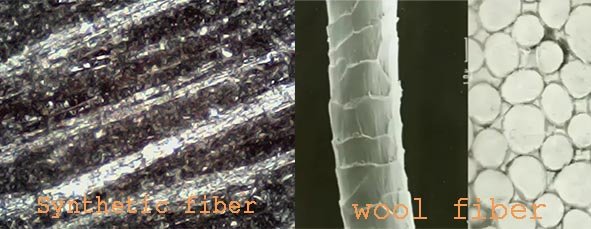

Unlike synthetic fibers (like acrylic or polyester), which appear smooth and glass-like under a high-powered microscope, natural wool fibers are covered in overlapping cuticle cells.

The Directional Friction Effect

These scales are arranged like shingles on a roof or the scales of a fish, pointing from the root to the tip. This creates a phenomenon physicists call the Directional Friction Effect.

- With the grain: If you rub the fiber from root to tip, it is smooth.

- Against the grain: If you rub it the opposite way, the scales flare out and lock together.

This is the secret sauce. When we create your pet’s portrait, we are utilizing these millions of microscopic scales to create a biological locking mechanism. Once these scales interlock deep within the core of the sculpture, they form a bond stronger than glue. However, how we get them to lock matters.

The Paradox of “Fiber Damage”: Construction through Destruction

This is a concept rarely discussed outside of professional fiber art circles. Needle felting is, by definition, a destructive process. We use sharp, barbed needles to puncture the wool thousands of times.

But there is a “Goldilocks Zone” of damage:

The Danger Zone: Excessive Damage (The “Over-Felted” Brittle Core)

If an unskilled artist uses the wrong gauge needle (too thick) or stabs too aggressively in one spot, they don’t just tangle the fibers—they break them. Under a microscope, you would see snapped fibers and pulverized scales. The result is a sculpture that feels hard but is actually brittle. Over time, these broken short fibers will simply fall out or crumble.

The Weak Zone: Insufficient Entanglement (The “Under-Felted” Puff)

This is the most common issue with low-cost commercial felting. To save time, the artist pokes just enough to make the wool hold a shape. The fibers are merely resting next to each other, not interlocked. There is no structural tension.

The Sweet Zone: Controlled Entanglement

Our artisans use a progression of needle gauges (from 36 gauge down to 42 gauge ). The goal is to catch the fiber scales and drag them just enough to hook onto a neighbor, without snapping the protein chain. This creates a flexible yet unbreakable matrix.

The Mechanics of the Poke: Needle Depth as a Structural Engineer

When people first hold one of our sculptures, they are always surprised: “It’s so firm!” That’s not an accident—it’s the result of treating wool like an engineering material, not a toy.

If a needle-felted pet feels “squishy” like a marshmallow, it’s a red flag. It means the creator only felted the surface “skin,” leaving a loose, hollow interior. Without a solid core, gravity is your enemy; within a year or two, the snout will flatten and the ears will sag.

The Physics of the “Deep-Core” Poke

To build a piece that lasts 10+ years, we use Deep-Core Entanglement. Think of it as building a skyscraper: you can’t support 50 stories with just surface plaster; you need steel rebar anchored deep in the foundation.

“In my studio, I rely on a symphony of sound and tactile feedback. I listen for a specific, rhythmic ‘crunch’—the whisper of thousands of wool scales interlocking deep within. As I drive the needle 30-40mm toward the geometric center, I wait for the resistance to mirror the firmness of a tennis ball, signaling a perfectly stabilized core. By anchoring surface fibers into this rock-solid internal matrix, we ‘lock’ your pet’s likeness into an everlasting form.”

The “Surface Tension” Trap (Cheap Manufacturing)

In industrial settings or hurried amateur work, the goal is visual speed. They use “shallow poking” (10mm – 20mm). This creates a “crust”—a hard outer shell that hides a soft, loose interior.

Why it fails: The outer crust is not anchored to anything. As humidity changes and gravity pulls, the loose core settles. The crust buckles. The ears fold. The legs splay.

The “Deep Core” Matrix (Heirloom Quality)

Our process involves driving fibers from the very surface all the way to the geometric center of the sculpture. We are essentially tying the “skin” of the sculpture to its “bones.”

We build the core under high compression until it feels dense and solid. Only then do we add the softer surface fur. This ensures that the structure supporting your pet’s likeness is immune to gravity.

The Anatomy of Collapse: A Timeline

To illustrate why this matters, let’s look at the timeline of a standard $80 felted pet versus a true artisan creation.

The Low-Cost Lifecycle

- Month 1: Looks great. Soft to touch.

- Month 3: “Shedding” begins. You find loose fibers on the shelf. This is because the scales weren’t locked, and the short fibers are migrating out.

- Month 6: Structural sag. The neck shortens. The distinct stop (forehead) of the dog flattens out. The air pockets inside are collapsing.

- Year 1: Deformation. The piece looks “tired.” It has lost the spark of life because the detailed muscles and expression lines have relaxed into a generic shape.

The Artisan Lifecycle

- Year 1: Identical to the day it arrived.

- Year 5: Still firm. The microscopic scales have settled into their permanent “locked” position.

- 10+ Years: The piece remains a dignified tribute, retaining the exact silhouette and expression of the pet it commemorates.

Not All Wool is Created Equal: The Science of Microns

Another layer of our quality control is the selection of the wool itself. We don’t just use “wool”; we select based on Micron Count (fiber diameter) and Crimp (natural waviness).

- Core Wool (Maori / Corriedale – 27-30 microns): We use these coarser wools for the internal skeleton. Their scales are large and aggressive, locking together tightly to form a rigid base.

- Surface Wool (Merino – 19-21 microns): We use fine Merino for the top coat. It mimics the softness of pet fur but is rooted into the coarse core.

Note: Cheap manufacturers often use synthetic polyester fillers (Poly-fil) for the core to save money. Polyester is slippery and has no scales. You cannot needle felt polyester into a solid mass; you can only stuff it. This is why cheap pets feel squishy—they are essentially stuffed animals masquerading as sculptures.

Comparative Analysis: The Data

| Feature | Standard Commercial Quality | Our Artisan Quality |

|---|---|---|

| Core Material | Polyester fill or waste wool (short fibers) | 100% High-Crimp Coarse Wool (Long staple) |

| Needle Depth | Surface to mid-layer (10–20 mm) | Full core penetration (reaching geometric center) |

| Estimated Needle Strokes | < 5,000 pokes | > 80,000 pokes |

| Entanglement Type | Loose friction (reversible) | Structural locking (irreversible) |

| Density Test | Can be squeezed like a sponge | Firm, resists compression |

The “Zizhou” Principle: Ancient Wisdom in Modern Art

Finally, we must acknowledge the heritage of this craft. While needle felting is a modern variation, the principles of durability come from ancient wet-felting traditions, such as the renowned Zizhou felt rugs of China.

The masters of Zizhou knew that to make a rug last 100 years, you couldn’t just press the wool; you had to torture it. They used heat, water, and intense foot-stomping pressure to force the wool scales to open and latch permanently.

While we cannot boil your pet replica (it would ruin the realistic fur texture!), we apply the same physics of compression through our “Deep Core” technique. We don’t stop poking when the shape is “good enough.” We continue until the core density matches that of a wet-felted object. We create a “memory” in the wool that resists change.

Conclusion: Investing in Permanence

When you look at the price tag of a custom artisan pet replica, you aren’t paying for the wool. You are paying for the physics. You are paying for the 80,000+ individual needle strokes that it takes to turn biological fiber into a permanent sculpture.

We refuse to cut corners because we build memories to last, ensuring that the pet you hold in your hands today is the same one you’ll smile at 10 years from now.

Frequently Asked Questions on Durability

Q: Why does it take 6-10 weeks to create one pet?

A: To achieve a density that lasts 10+ years, we need over 80,000 controlled needle pokes. This cannot be rushed by machines.

Q: Why does the sculpture feel hard to the touch?

A: That hardness is a sign of quality! It means the core has been compacted to ensure the legs, neck, and ears never sag over time.

Q: How do I keep it looking new?

A: Our sculptures repel dust better than soft fabrics. We include a premium display cover with every commission.

- Use a soft makeup brush to whisk away dust.

- Use a hair dryer on the coolest, lowest setting.

- Never use water or detergents. Moisture can cause unwanted shrinkage.